Ningbo Xinda Screw Compressor Co., Ltd.

Two Stare Compressor,Compressor for Mining,AUGUST Compressor for Mining

Ningbo Xinda Screw Compressor Co., Ltd.

Two Stare Compressor,Compressor for Mining,AUGUST Compressor for Mining

Model No.: XGT132

Brand: AUGUST

Packaging: wooden case

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Certificate: IS9001/ISO 14001/ CE

HS Code: 8414809090

Port: NIINGBO

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW,FCA

High efficiency and energy saving

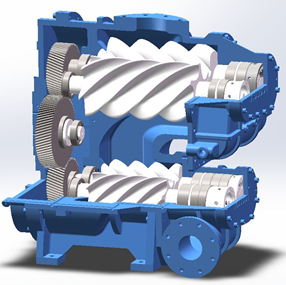

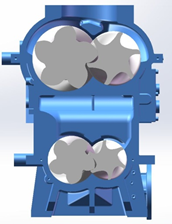

First stage compression unit and the second stage compression unit are integrated in one air end driven directly by the helical gear, the optimal linear speed for each stage.

After the first stage compression, constant pressure compression by intensify spread oil cooling, reduce the second stage compression suction temperature, ensure that the second stage compression unit is close to isothermal compression.

Compression ratio reasonable distribution, optimized bearing design, second stage compression reduces the compression ratio of each stage, reduces internal leakage, improves the volume efficiency, reduces the bearing load, and improves the life of the air end.

In the same power, double stage compression energy saving is 15% more than the single stage compression.

The latest generation of efficient XA series rotor type line

Latest generation of XA series bilateral asymmetric optimization of rotor type line, male and female rotor 6/5 tooth number ratio.

"XA" series rotor type line, using SKF Cylinder and Angle contact ball high efficient bearings, bearing lifetime more than 100,000 hours.

big rotor, low speed, high precision, high efficiency, low noise, low vibration, high reliability, long lifetime design , adhering to the "high efficiency, energy saving, reliable, durable" manufacturing philosoph

Finite element assisted optimization design

Deeply analyze the reasons for the double stage compression energy saving

According to the working principle of Screw Compressor, isothermal compression process is the most economical.

The figure below shows the indicator diagram of the overall compression process. The curve 1-2'-3' is the isothermal compression process, and the area of 6-1-3'-4 is the indicator work of isothermal compression.

Curve 1-2-3 "is the normal single stage compression process, and the area 6-1-3"-4 is the indicator work of normal single stage compression.

The curve 1-2-2'-3' is the AUGUST double stage compression process, and the area of 6-1-2-2 '-3-4 the indicator work of AUGUST double stage compression.

From here you can see that the isothermal compression process '6-1-3-4 area is smallest (minimum indicated work), but in actual can't achieve isothermal compression,while AUGUST double stage compression more energy saving than normal single stage commission .

High precision filtration separation system

1μm precision air filter, 10 μm precision oil filter,

large capacity design standard to ensure the compressor Long-term efficient and safe operation.

oil content≤3ppm,which provides you with a cleaner air source.

High safety control valve system

high quality inlet control valve, Large caliber, small resistance, precision casting

Reliable check valve, low fluid resistance, good sealing, quick closure

High quality minimum pressure valve, low pressure loss, open and close safety and reliability

temperature control valve prompt response, to avoid the condensed water

The fluoro rubber with O ring , the invisible place gives you the visible safety

Reliable cooling system

Large heat dissipation area design, avoid to high temperature stop.

Axial flow cooling fan, large air volume, Suction structure, heat evenly.

2 fan design, determine the number of starting fans according to the discharge temperature.

Unique cooling flow field with low noise.

Mixed flow system temperature control valve

Between first and second air end Inject cooling oil, in order to ensure the interstage compressed air temperature is always above the dew point temperature, using patent design of mixed flow system temperature control valve ,achieves the good interstage cooling and prevent the formation of liquid water, avoid corrosion and system oil emulsion problems

The third generation high efficiency permanent magnet motor

Insulation grade F, protection grade IP54,adapt to the bad environment.

Split design, easy maintenance.

Without gearbox design, motor is connected directly with rotor through the coupling, high transmission efficiency.

Low temperature rise, independent cooling fan design, so that the motor cooling is not affected by the speed regulation.

With PT100 temperature protection switch to avoid high temperature degaussing.

Large speed range, high precision and large adjustment range.

high temperature magnetic steel UH, 180 ℃ not break the magnetic.

permanent magnet motor is 3%~5% higher than normal motor, and constant efficiency.

The 3rd generation INOVANCE MD series inverter

Constant pressure supply: the supply pressure is precisely controlled under 0.01 MPa.

Eliminates empty load, reduces the empty load energy consumption by 45%.

Eliminate overpressure

Variable Frequency range is 30%~ 100%, which is larger than the general frequency range.

vector air supply, accurate calculation, ensure that the air volume of Air Compressor is consistent with the demand of the user system.

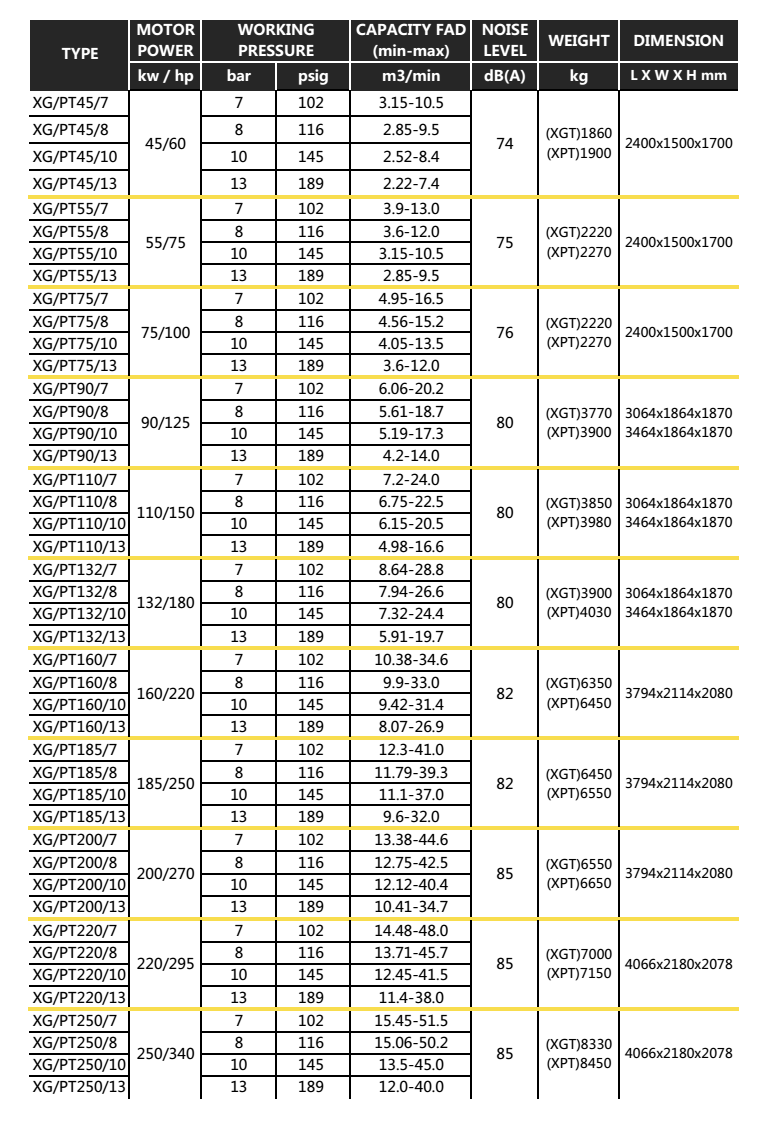

Specification

| modle | XGT132/7 | XGT132/10 | XGT132/13 | XGT132/8 | |

| compressor | type /control mode | two stage /load-unload control | |||

| free air delivery (m3/min) | 28.8 | 24.4 | 19.7 | 26.6 | |

| working pressure (MPa) | 0.7 | 1.0 | 1.3 | 0.8 | |

| air flow adjustment | load-unload | ||||

| inlet pressure (MPa) | 0.1 | ||||

| working temperature (℃) | -5~40 | ||||

| discharge temperature (℃) | <105 | ||||

| outlet temperature (℃) | under environment temperature +15℃ | ||||

| outlet oil content (ppm) | ≤3 | ||||

| air end vibration(mm/s) | ≤11.2(GB/T 7777) | ||||

| drive | coupling direct drive | ||||

| pipe size | DN65 | ||||

| lubricant(L) | 110 | ||||

| Microcomputer control | discharge pressure, discharge temperature, current, maintenance reminder, failure alarm, intelligent operation, linkage control and remote start and stop, and Internet of things (optional) | ||||

| safety protection device | Safety valve, high discharge temperature, high discharge pressure, over current, underphase, reverse phase | ||||

| maintenance indicator | Air filter, oil filter, oil and air separator filter , lubricating oil, grease | ||||

| noise dB(A) | 80±3 | ||||

| dimension (L×W×H)(mm) | 3064×1864×1870 | ||||

| weight (kg) | about 3900 | ||||

| motor | power (kW) | 132 | |||

| type /start method | Asynchronous motor/star delta start | ||||

| cooling method | air cooled | ||||

| voltage /frequency /speed /pole | 380V/50Hz/1485/4 | ||||

| IP grade | IP55 | ||||

| insulation grade | F | ||||

| cooling system | cooling method | air cooled | |||

| control | intelligent control | ||||

| type / Installation | cooling fan/Suction | ||||

| power (kW)/numbers | 3.5×2 | ||||

| Air Flow(m3/h) | 18500×2 | ||||

Personalized intelligent control system

1. Q: What is used for?

A: Machining, mining, shipbuilding, water conservancy, or energy automobile, cement, textile, food,

medicine, highway, railway or urban construction

2. Q: What is the Pressure?

A: We can supply pressure 7 / 8 / 10 / 13 BAR

3. Q: Air capacity (motor power )

A: From 5.5 KW to 250 KW

4. Q: Protection grade

A: IP54

5. Q: Certificate?

A: ISO 9001:2008, ISO 14000:2004, CE

6. Q: Delivery time?

A: Regular products 30 days

7. Q: What is the packing?

A: Wooden case

8. Q: Warranty

A: 18 months related parts warranty and 2 years air end warranty

Product Categories : Two Stage Screw Air Compressor > Two Stage Regular Screw Air Compressor